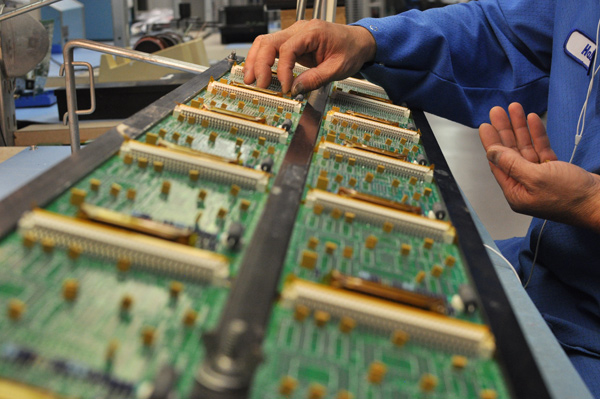

Printed Circuit Board Assembly - PCB Assembly

QCMI provides complete contract manufacturing services for assembly of most printed circuit board technologies in use today. From simple circuit boards utilizing thru-hole technology to complex multi layer, ultra-fine pitch SMT, and BGA devices, QCMI has the manufacturing capability. Our equipment and personnel are the finest available and consistently produce products in the most efficient and cost competitive ways possible.

Electronic Excellence

For printed circuit board assembly manufacturing to be efficient and yield high quality, the entire process relies on accurate process engineering. Our highly skilled and trained workforce uses the documentation, tools, and equipment to manufacture circuit board assemblies with precision and unsurpassed workmanship.

Surface Mount Technology

QCMI uses only precision engineered and manufactured laser cut, stainless steel stencils for solder paste application. Components are placed with extreme speed and optical precision using our Hydra-equipped MYDATA pick and place equipment. Our 8 zone convection oven gives the control to precisely reflow all board types and component technologies including; large and heavy-plane PCBs, BGA and ultra-fine pitch components. Learn more about our manufacturing equipment on our Equipment Page.

Thru-Hole Technology

For printed circuit board assembly utilizing thru-hole technology, we offer complete manufacturing solutions. Component prep, load, and hand soldering are performed using a variety of methods and chemistries. Wave soldering is done using our Vitronics/Soltec Delta wave soldering system and flux residue is removed with an EMC/H20 inline cleaning system utilizing de-ionized water. Learn more about our manufacturing equipment.

Teamwork

The QCMI production department is composed of manufacturing teams specializing in the various skills required to accomplish each task. We have found the team format to reduce the variables in the manufacturing process and yield more consistent products.